China steps up readiness to handle logistical complexities of global COVID-19 vaccine distribution

The cargo shipment of COVID-19 vaccines produced by the Chinese company Sinovac Biotech is being dispatched at the Cumbica airport in Guarulhos, Sao Paulo state, Brazil, on July 20. Photo: AFP

With

the coronavirus vaccine possibly ready for public use as early as November, the

rapid rollout of the vaccine candidates still poses great logistical challenges

in global vaccine transportation.

Though China has not yet exported COVID-19 vaccine candidates for non-clinical

trials use, all stakeholders in the supply chain, from vaccine producers to

relevant departments and logistics providers have been fully prepared for

global transportation to meet unprecedented challenges. International

organizations promoting equal vaccine distribution around the world have also

shown support to cope with potential threats.

Working on shipping schedule

China has promised to give the priority access to a vaccine to a list of

countries, mostly in Southeast Asia, Africa and Latin America. Many countries

may have to rely on China for global transportation of the COVID-19 vaccine,

considering its advanced equipment and more developed logistics system. China's

three leading coronavirus vaccine providers - Sinopharm, CanSino, and Sinovac -

are working out detailed plans for international procurement and transportation

with relevant authorities, a senior expert working with SF Express, who is

charge of COVID-19 vaccine global logistics but prefers not to be named, told

the Global Times on Monday.

The top vaccine producer Sinopharm has so far received COVID-19 vaccine orders

for more than 500 million doses, but its current production capacity cannot

satisfy all the orders, said the anonymous expert. Shortages of packaged

materials such as glass bottles and rubber plugs are also limiting the speed at

which Sinopharm can currently export its vaccines.

To save packaging materials, another frontrunner company CanSino will export

the raw pulp used to develop the COVID-19 vaccine in cans instead of directly

exporting the packaged vaccine, according to the senior expert.

China's vaccine suppliers and logistics companies are consistently working on

plans for international transportation routes in recent weeks, and are in close

communication with relevant international organizations and airlines. Chinese

vaccine manufacturers are also actively seeking export licenses from the

Chinese government.

International shipments of Chinese-produced vaccines to overseas markets are

expected to begin as early as mid-December. The transportation plan should be

specified at least one month in advance in order to settle down the financial

bill and equipment purchase, the expert added.

"For example, the cost of transporting vaccines to Brazil on charter

flights is about 7 million yuan ($1.05 million), so it is likely airlines will

stop at the transfer station and replenish other sources in transit to balance

economic costs. But stopping is a greater risk for the vaccine, requiring more

professional equipment," said the expert.

The World Health Organization estimates up to 50 percent of vaccines may be

wasted globally every year due to temperature control, logistics and

shipment-related issues.

"COVID-19 vaccine distribution will be unlike any previous

logistical challenge. It will need to reach nearly 200 countries in a

relatively short timeframe and will need to move in a safe and secure manner to

ensure full compliance with cool chain temperature requirements," Glyn

Hughes, head of cargo at the International Air Transport Association, told the

Global Times in a recent interview.

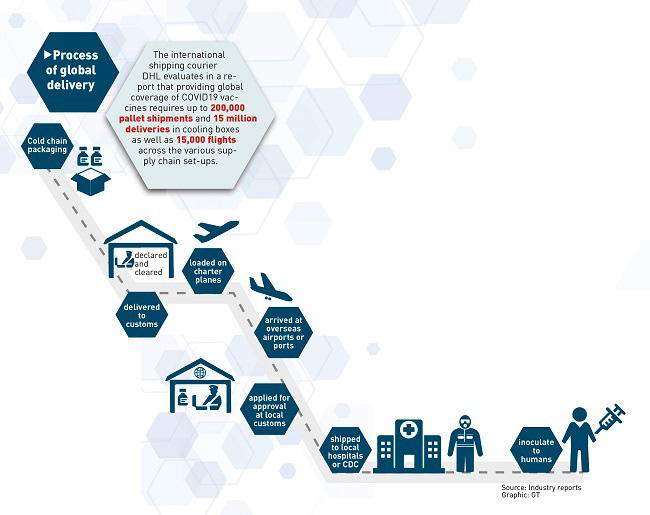

Other

difficulties lie in shortages of supporting facilities and high cross-border

transport costs. The international shipping courier DHL evaluated in a report

that providing global COVID-19 vaccine coverage requires up to 200,000 pallet

shipments and 15 million deliveries in cooling boxes, as well as 15,000 flights

across supply chain set-ups.

As the transportation trading volume of vaccines increases, international

freight market prices may surge when vaccines start to be shipped. But given

the pandemic, customs clearance approvals are either stagnant or slowing down

in many countries. This exacerbates the difficulty, Chen Yong, manager of the

Lengwang Technology Co., which provides cold chain solutions for traditional

medical products logistics, told the Global Times.

The cold-chain challenge

A lack of a certain assessment of the COVID-19 vaccine's thermal stability

could mean more rigorous temperature control along the vaccine supply chain,

with certain types of coronavirus vaccine (mRNA) requiring storage in

facilities as low as -70 degrees Celsius, while some other types - such as

inactivated vaccines - need temperatures at the conventional range of 2-8

degrees Celsius.

Overheating may compromise the vaccine or cause adverse reactions and even

death to the human body without clear evaluation.

"The air cargo supply chain is complex in normal conditions. When you

then include the additional challenges of cool chain requirements associated

with least developed countries, that complexity is magnified," said Glyn

Hughes. "Airport infrastructure is one area that will require close

scrutiny to ensure that vaccines are flown into appropriate facilities.

In-country supply chains will also need to be upgraded in many developing

nations to ensure the temperature integrity is maintained throughout the

journey from production to injection."

The freezing package of the vaccine is usually effective for five days during

transnational journey which takes at least two or three days from packing to

landing. If transit is involved, it will take longer, and bring a bigger

challenge for temperature-monitoring systems and storage space at the transit

station, Chongqing Zhifei Biological Products, a company manufactures and sells

vaccines and biological products, told the Global Times.

Emirates SkyCargo announced to have the world's first dedicated airside cargo

hub for the vaccine in Dubai on October 23.

Emirates SkyCentral DWC has more than 4,000 square meters set aside for

temperature-controlled GDP-certified dedicated pharmaceutical storage, allowing

for large-scale storage and distribution of the potential COVID-19 vaccines.

Overall, it is estimated that the facility can hold around 10 million vials of

vaccine at a range of 2-8 degrees Celsius temperature at any one point of time,

the airline company suggested in a statement sent to the Global Times.

A staff member works during a media tour of a new factory built to produce a COVID-19 vaccine at Sinovac, one of 11 Chinese companies approved to carry out clinical trials of potential coronavirus vaccines in Beijing on September 24. Photo: AFP

Global

support

As part of global efforts to strengthen vaccine supply chains and achieve

better immunization equity and coverage, in 2015, the Vaccine Alliance (GAVI),

UNICEF and other partners launched the Cold Chain Equipment Optimization

Platform (CCEOP) - a $400 million, five-year project to upgrade existing cold

chain equipment in 56 countries by 2021. Strengthening cold chains also

supports agile vaccine response efforts for infectious disease outbreaks,

including the COVID-19 vaccine when it becomes available, according to UNICEF.

"The key constraint in 2021 will not be potential intellectual property

dispute, but rather supply constraints, and addressing these issues will

require utilizing all available expertise and resources - including that of

industry," GAVI spokesperson told the Global Times. So far, the

organization has already secured up to 200 million doses of a vaccine for

lower-income countries.

"Technology transfer can succeed only when the innovator company works

closely with the recipient in order to replicate the complex manufacturing

processes in the new facility, and both partners are committed to overcoming

the many challenges that can emerge. Consequently, any partnerships in pursuit

of this goal must be viewed as advantageous from both sides," the

spokesperson said.

Sheikh Abdullah bin Mohammed al-Hamed, chairman of the Department of Health of UAE, is undergoing a clinical trial for the third phase of the inactive vaccine for COVID-19 in Abu Dhabi. Photo: AFP