Unilever to further ramp up innovation in country

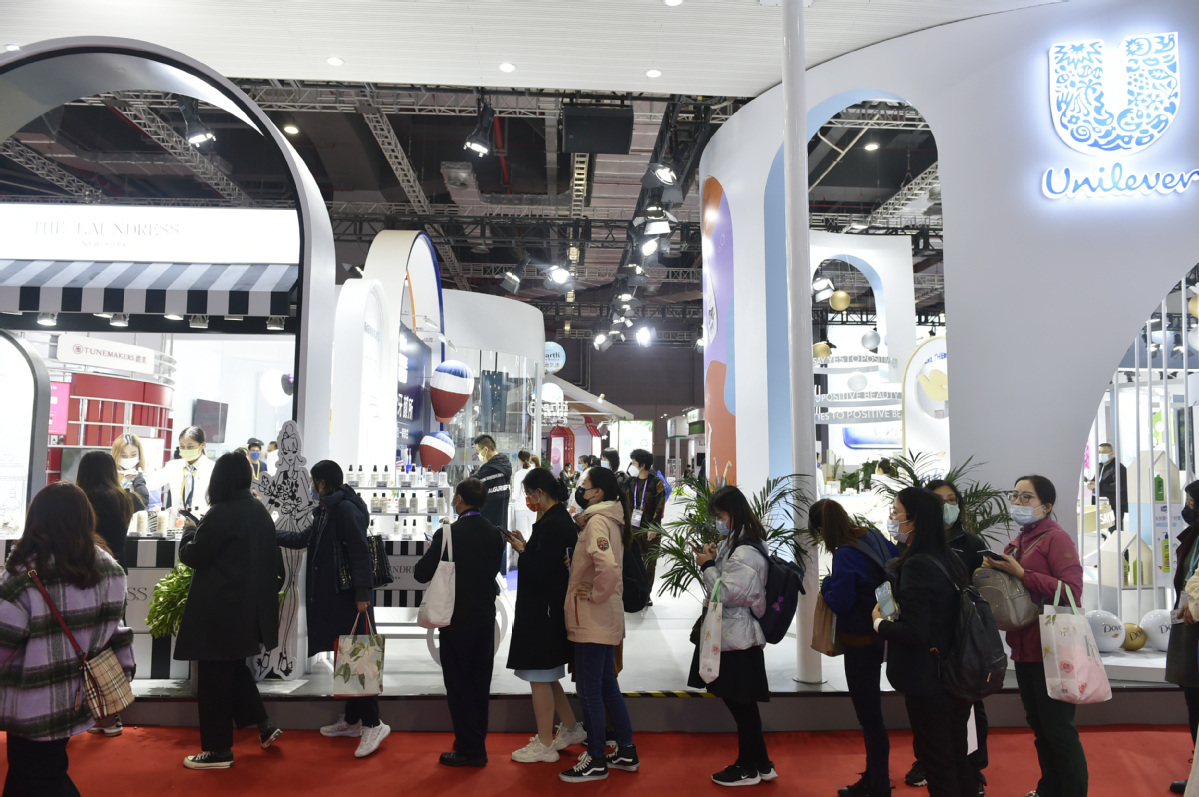

Visitors gather at the Unilever booth during the fourth China International Import Expo in Shanghai on Nov 8. [Photo/Xinhua]

Consumer product giant Unilever will begin to build a "net zero "plant in China from the end of this year, as the company bets big on the country as a source of innovation, a senior executive said.

Unilever is allocating some 130 million euros ($146.3 million) to the first phase of the full-category plant in Guangzhou, Guangdong province, and make it an industry-wide benchmark facility for zero emissions, said Zeng Xiwen, vice-president for Unilever. To be operational by 2023, the facility is designed to manufacture personal care, household and food products.

"We are highly confident of the Chinese market, as the local government walks the talk by truly upholding high-level opening-up. So, we want to put our best technologies and biggest commitment here," Zeng told China Daily during the fourth China International Import Expo earlier this month in Shanghai.

"For multinational corporations, globalization is our lifeline. So we position ourselves as the 'natural ally' of reform and opening-up and fend off so-called de-coupling," he said.

A slew of favorable policies has catapulted Unilever China to the forefront of world-pioneering endeavors. For instance, its manufacturing site in Hefei, Anhui province, has been recognized as an "Advanced 4th Industrial Revolution Lighthouse" by the World Economic Forum in collaboration with consultancy McKinsey & Co.

This certifies manufacturing sites that lead in digital industrial technology space, such as flexible manufacturing to better tailor to customer needs and using digital means to enhance business efficiency.

For Unilever, China is also the very pivot in generating globally applicable original ideas and then turning these prototypes into tangible products, such as the company's toothpaste brand Regenerate, which is a brainchild of its Shanghai-based research and development center, one of Unilever's six R&D facilities worldwide, following a decade of in-house research, said Peter Schrooyen, vice-president for R&D at Unilever China.

"It's a truly global innovation center. This premium product, protected with proprietary NR-5 technology, was jointly developed by domestic and foreign R&D teams and was successfully launched in Europe. We could act as a bridge, connecting domestic and international circulation, including through our approach to open innovation," Schrooyen said.

Regenerate toothpaste, which debuted in the United Kingdom and then rolled out globally seven years ago, becomes a sought-after product in China, thanks to the fourth CIIE and cross-border e-commerce channels.

"The product exemplifies how we truly realize the global co-creation and sharing of Chinese technology. The Shanghai center will also continue to promote product technology upgrades with innovation to better empower Chinese and global consumers," Schrooyen said.

Zeng agreed, adding one significance of the CIIE is that "it provides a channel to maximize exposure among our stakeholders, paving the way for the localized production of high-quality products in the future".

Zeng said the Shanghai center encompasses all three core functions including the most important one, "fundamental research", which targets forward-looking innovation that has been visionary and industry-leading for around a decade.

The entire consumer goods industry is expected to continue its momentum, boosted by the changes introduced by COVID-19 as well and the return of fundamental pre-pandemic trends, consultancy Bain &Co said earlier this year.

For instance, a rise in hygiene awareness led to a 3 percent volume gain in personal care products such as personal hygiene goods. Sales of ice-cream also picked up as consumers sought comfort food due to the pandemic, said Derek Deng, a Bain partner based in Shanghai.